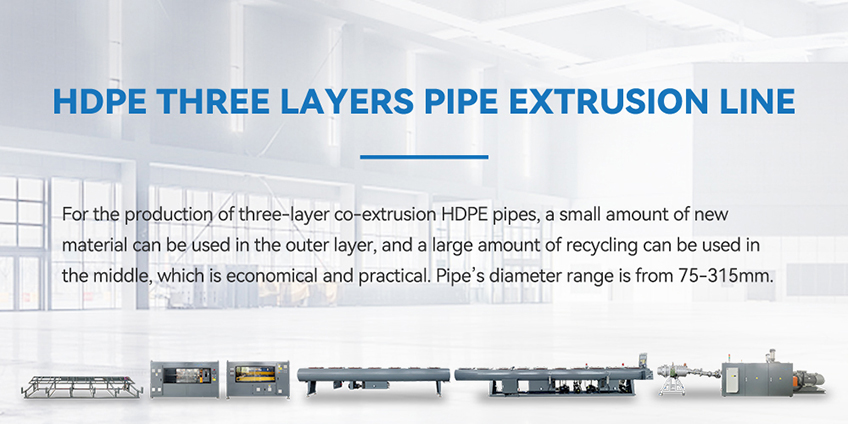

HDPE Multiple Layers Pipe Extrusion Machine

Inquire

High Electric Saving

Servo motor and servo system, it brings 15% electric saving

High Production Standard

CE standard electric cabinet design

High Degree Of Automation

Remote assistance and Intelligent diagnosis

Three-layer HDPE pipe extrusion line contains these machines : Single screw extruder, Die head, Vacuum calibration tank, Spray cooling tank, Haul-off, Dust free cutter, Stacker, Hopper dryer, Vacuum feeder, Gravimetric control system.

| No. | Machine | Qty |

| 1 | Vacuum feeder | 2sets |

| 2 | Plastic hopper dryer | 2sets |

| 3 | Gravimetric dosing unit | 2sets |

| 4 | PLMSJ75/38 single screw extruder(PLC control) | 2sets |

| 5 | PLMSJ25/25 single screw extruder | 1set |

| 6 | Die head 75-315mm(3-layer) | 1set |

| 7 | 315mm Vacuum calibration tank | 1set |

| 8 | 315mm Spray cooling tank with roundness calibrator | 3sets |

| 9 | Four claws haul off(servo motor) | 1set |

| 10 | Dust free cutter | 1set |

| 11 | Stacker | 1set |

| 12 | Laser printer | 1set |

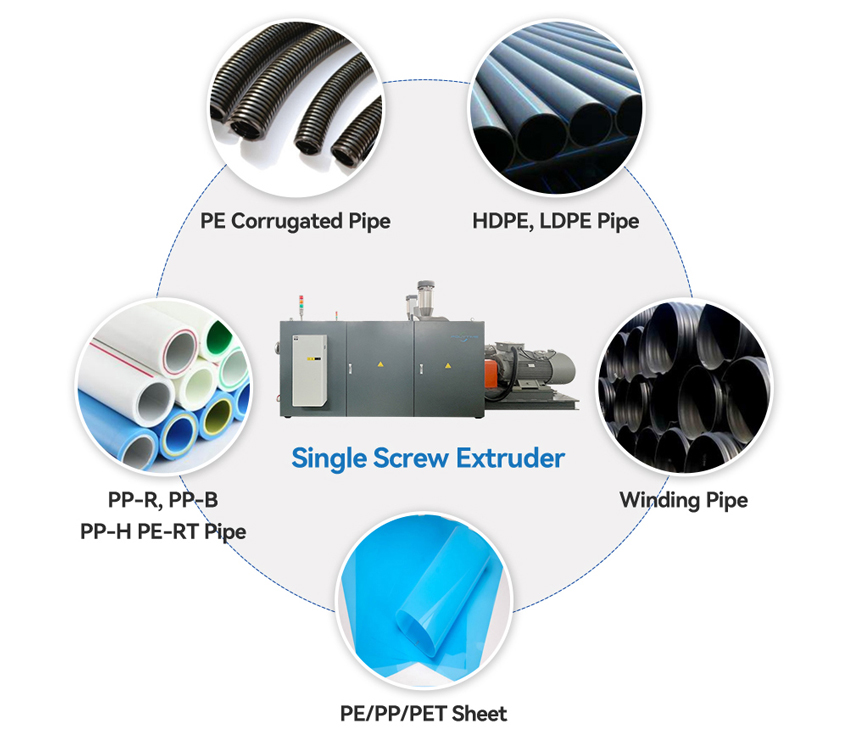

- Wide Applications -

- Advantage -

Single Screw Extruder

● 38 L/D ratio screw and barrel guarantees higher output and better plasticizing

● Higher output and range from 800 to 1000kg/h

● High speed PE pipe extrusion ,up to 15m/min

● High torque gear box from FLENDER (Germany)

● Gravimetric dosing unit from iNOEX(Germany), controlled by PLC to achieve accurate raw material feeding of each extruder

● With platform for vacuum feeders and dryer hoppers

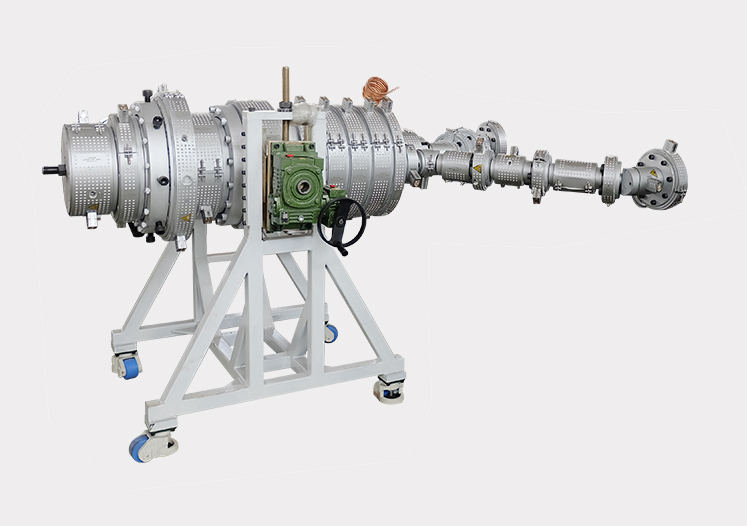

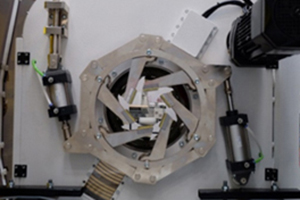

Mould

● The multi-layer spiral mold is designed according to the ratio of different layer, reasonable distribution of mold cavity flow channel ensures even layer thickness and better plasticizing effect.

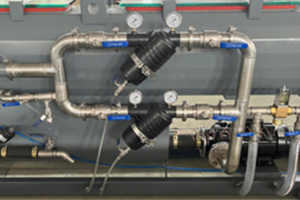

Vacuum Calibration Tank

European type big plastic filter (With 1pcs filter as spare part)

Water level adjustment: Point contact control

Water temperature adjustment: Expansion valve

Spray cooling system

Pipe height unification adjust: Adjustable pray angle

Gas & water separator

Haul Off

● Cantilever type encoder

● Nylon strip design, avoid chain loosing from the rack under high speed running

● Tractor motor adopts servo control

Cutter

● Universal clamp

● Synchronous Device

● Servo motor controls fly knife for small pipe's cutting

● Italy Hydraulic System