ERW Steel Tube Mill Line

InquireERW Steel Tube & Pipe Mill Line

- Advantage -

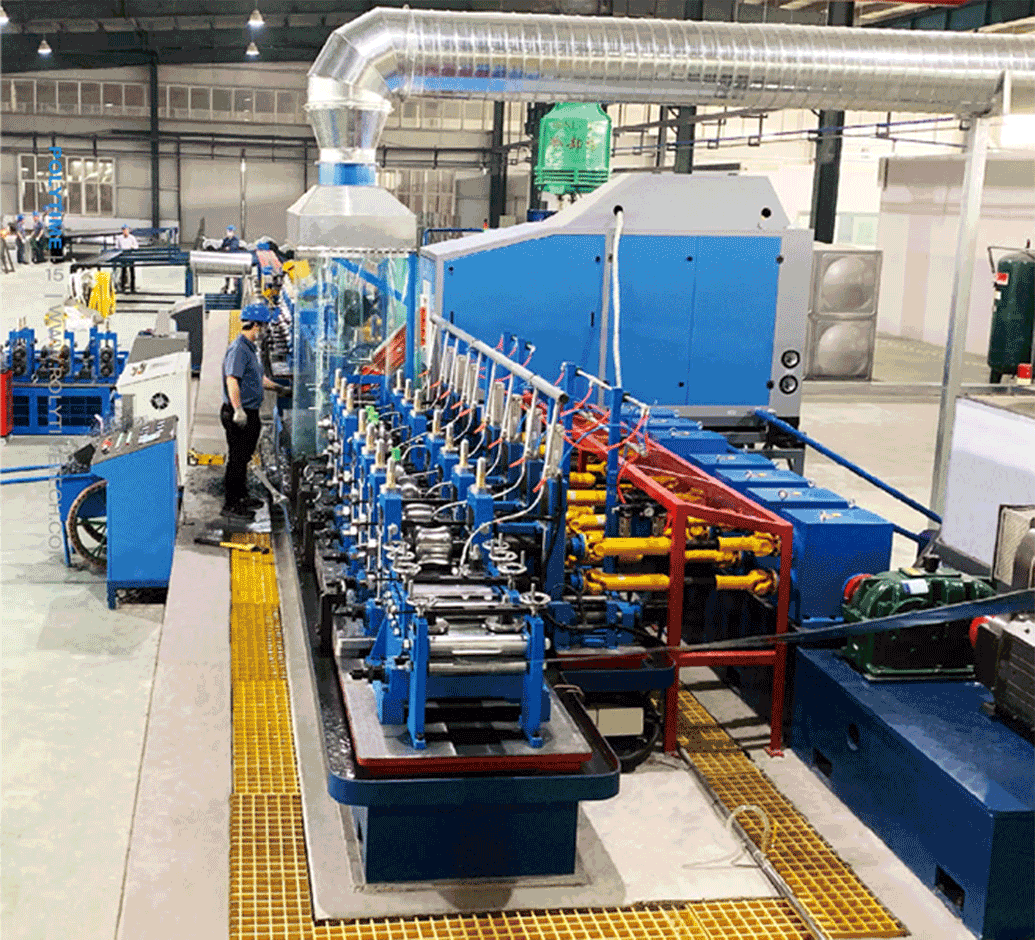

Durable and non-deformed machine base

Use thick steel to weld together as a whole to tempering more than 4 hours twice to make sure that the machine can be used in long term without deformation.

Screw protection

Using bronze adjusting nut to protect screw, absorb shock as its self-repairing characteristic.

Long bearing life

Equipped with greasing nozzles for the bearing lubrication, the bearing life is largely improved.

Quick positioning

AlI the positioning keyways and bolt holes are processed by CNC machines, with high accuracy.

Intelligent system

On-line and automatic Roller

Quicker-Change System

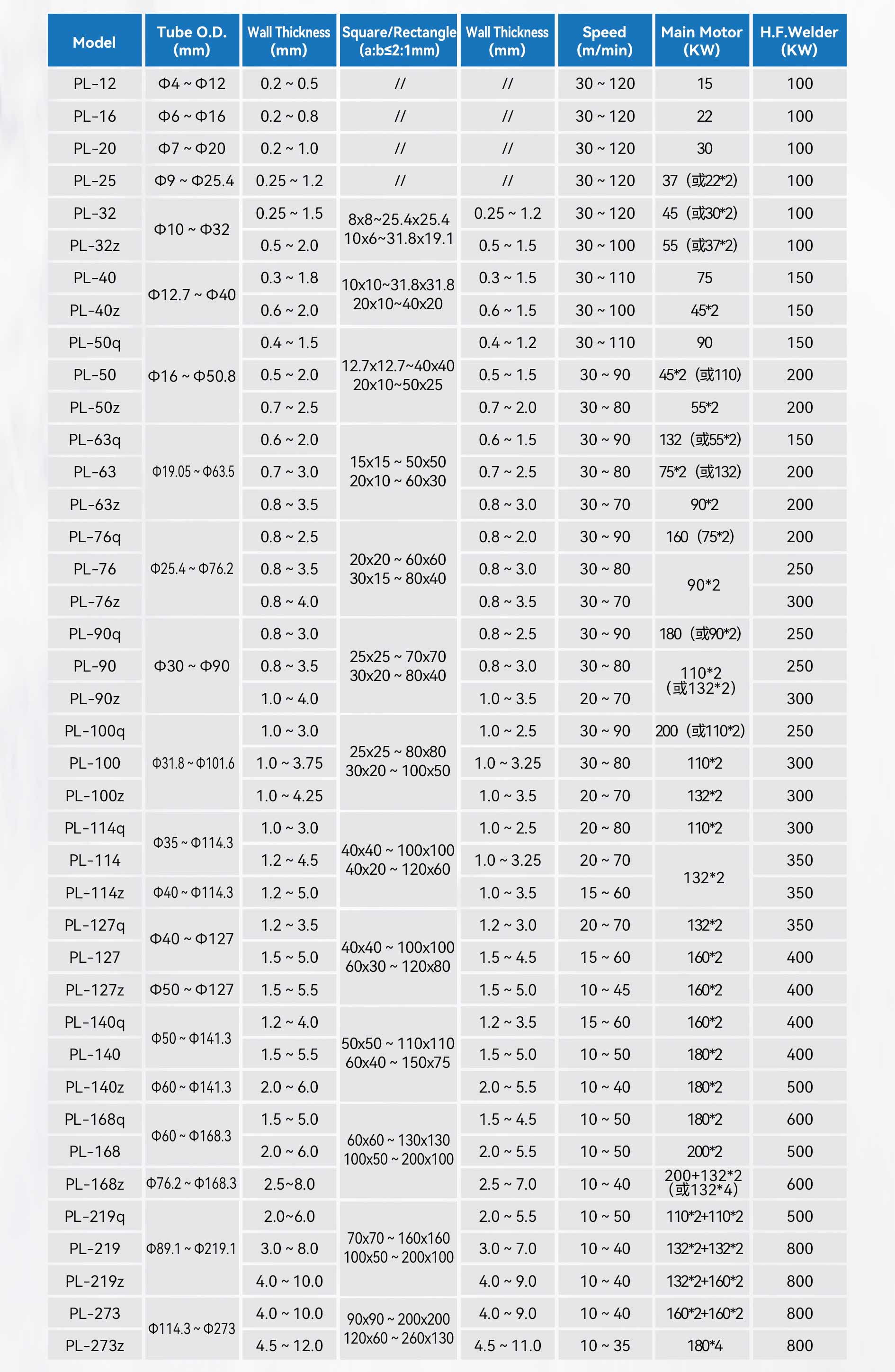

- Technical Parameter -

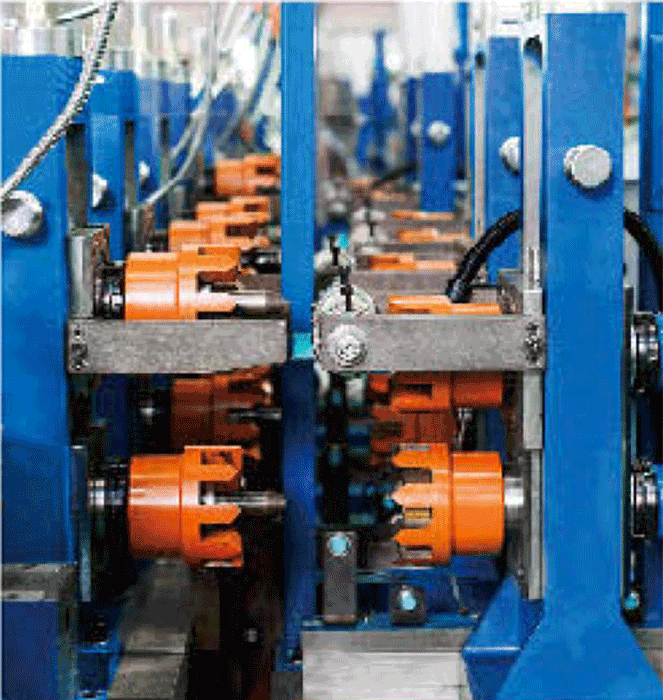

Roller Quick Change System

10 min

Change roller in 10 minutes

30 min

Resume production in 30minutes

When changing the pipe size to another one, the rniddle stands with universal coupling systern move backward and release automatically from the upper and lower horizontal shafts, which iS driven by motor or hydraulic system.

For small and middle model machines, lift the whole platform with horizontal & vertical stands and rollers away from the machine base, then lift another same platform with the required pipe roller installed off-line to the machine base, the middle stands with universal coupling system move forward and automatically combine the upper and lower horizontal shafts, which is driven by motor or hydraulic system.

For small and middle model machines, lift the whole platform with horizontal & vertical stands and rollers away from the machine base, then lift another same platform with the required pipe roller installed off-line to the machine base, the middle stands with universal coupling system move forward and automatically combine the upper and lower horizontal shafts, which is driven by motor or hydraulic system.