HDPE Pipe Extrusion Machine

Inquire

- Wide Applications -

PE Corrugated Pipe

HDPE, LDPE Pipe

PP-R, PP-B PP-H PE-RT Pipe

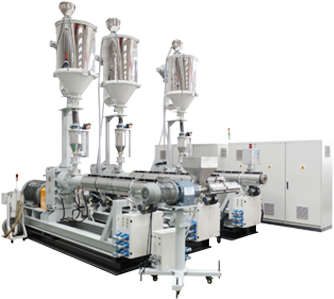

Single Screw Extruder

Winding Pipe

PE/PP/PET Sheet

- Advantage -

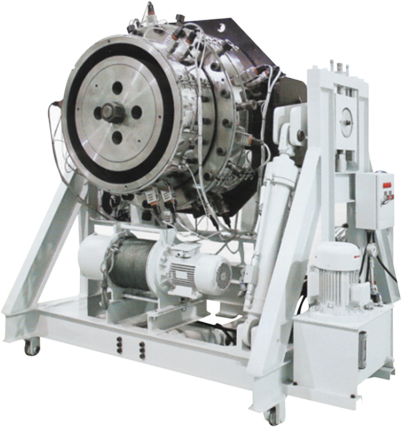

Single Screw Extruder

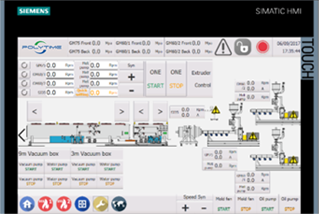

Siemens PLC control system

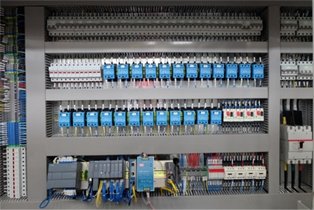

Europen standard electric components,

high and weak electricity isolation

Gravimetric dosing system

Discontinuous mode ceramic heater

Adopted imported fan

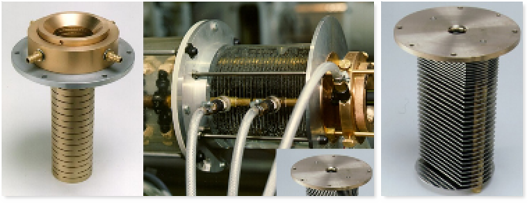

Mould & Calibrator

Mould

● Top material ensures mould using life

●Uniform chromeplate & thicker

●Advanced channel design brings faster extrusion

●Internal heating rises heating eficiency, ensuring uniform heating

●Independent temperature control unit

●Heating recycling system,energy saving

●Equpped with trlley, convenient moving

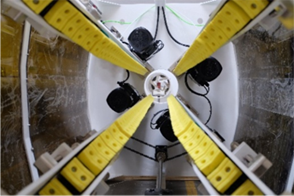

Calibrator

●Tin bronze material calibrator, shrink ratio is low, anti-corrosion, high hardness, not easy to deform

●Disk type calibrator makes more contact area with water, ensuring fast cooling

●Water flow control system guarantees water support & pressure

Vacuum Calibration Tank

Point contact type water level control system

Mechanical expansion valve(Danfoss)

Water flow meter control

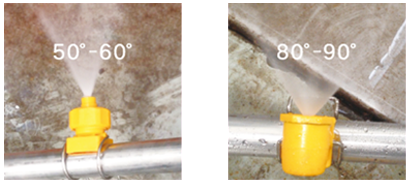

Advanced pipe line layout design and adjustable spray angle for better cooling effect, dense pipe line in the first zone for fast cooling

According to the pipe diameter, adopt dfferent designs for dfferent

spray arc.

European technology can ensure efficient and stable running.

It comes with stainless steel buckde fixing for easy installation.

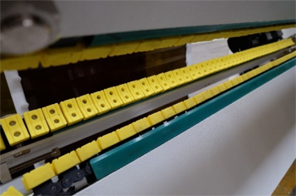

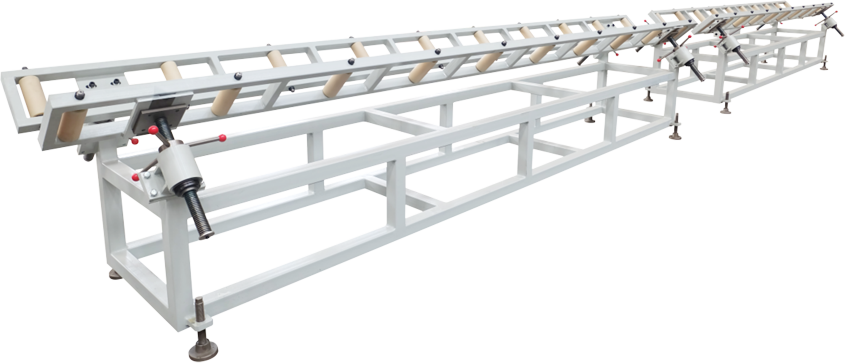

Haul Off

The rubber block increases the slicone component by 30%, the friction coefficiency is increased by 40%,

and the service life is doubled. Quick-opening structure improves replacement efficiency and enables non-stop replacement.

Nylon strip design, avoid chain losing from the rack under high speed running

The lifting mechanism adopts two-stage design: cylinder & screw.

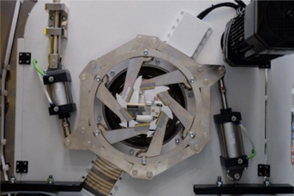

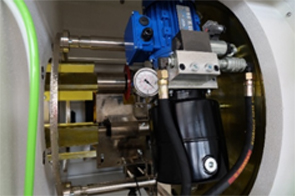

Cutter

The universal clamp adopts a screw shaft and a positioning shaft matching structure.

The return air cylinder is placed on the cutting device. This design ensures the stability during the

return process and improves the cutting accuracy.

Cutting unit

Max Cutting Thickness: 70mm

Italian hydraulic system

Blade from Korea

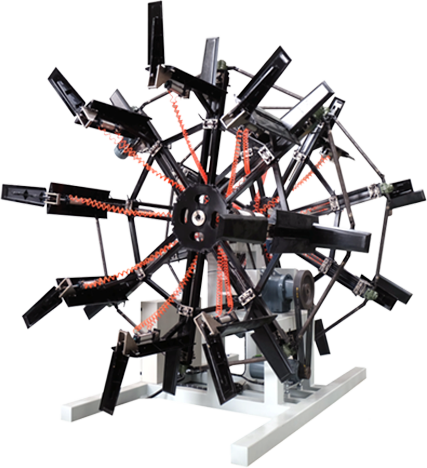

Coiler

40 type single/double station coiler

63 type single/double station coiler

110 type single station coiler

Stacker

1.Pneumatic control, stainless steel(for 0.D≤250mm)

2.Adjustable included angle for different OD pipe(for 0.D2250mm)

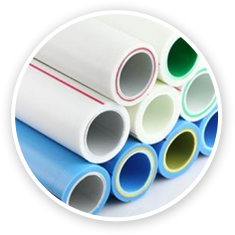

- Technical Parameter -