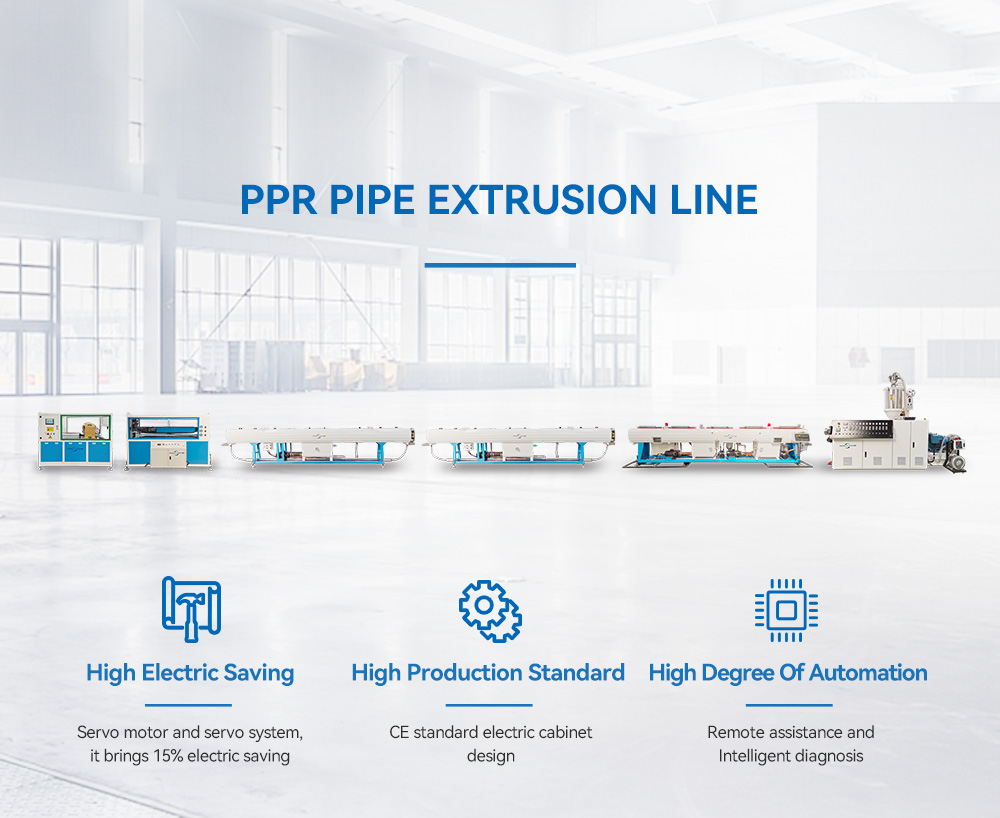

PPR Pipe Extrusion Machine

Inquire

- Wide Applications -

PE Corrugated Pipe

HDPE, LDPE Pipe

PP-R, PP-B PP-H PE-RT Pipe

Single Screw Extruder

Winding Pipe

PE/PP/PET Sheet

- Advantage -

Single Screw Extruder

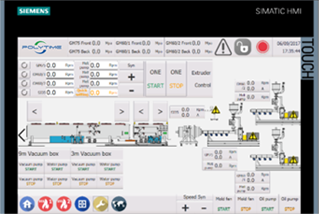

Siemens PLC control system

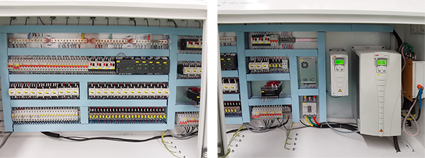

All electric is national brands, with stable performance and global warranty. Schneider, LS, ABB, WEG, etc.

Gravimetric dosing system

Discontinuous mode ceramic heater

Adopted imported fan

Vacuum Tank & Cooling Tank

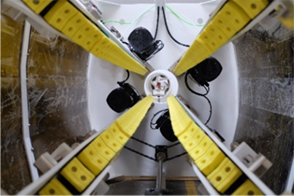

Whole tank material is SS304

Centralized water inlet and drainge design

Big European type filter for stable filter effect

Lighting design is easy for workers to operate

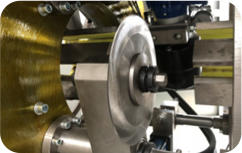

Haul Off

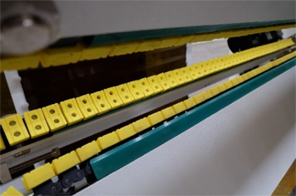

The rubber block increases the slione component by 30%, the friction coefficiency is increased by 40%, and the srice life is double.

Quick-opening structure improves replacement efficiency and enables non-stop repllacement

Nylon strip design, avoid chain loosing from the rack under high speed running

The lifting mechanism adopts two-stage design: cylinder & screw.

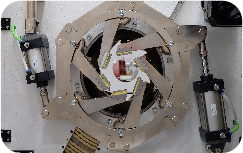

Cutter

The universal clamp adopts a screw shaft and a positioning shaft matching structure.

The return air cylinder is placed on the cutting device. This design ensures the stability during the

return process and improves the cutting accuracy.

Cutting unit

Max Cutting Thickness: 70mm

Italian hydraulic system

Blade from Korea

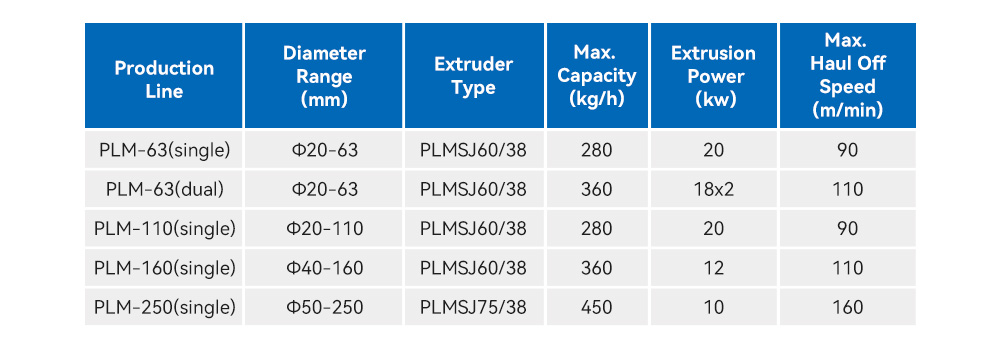

- Technical Parameter -