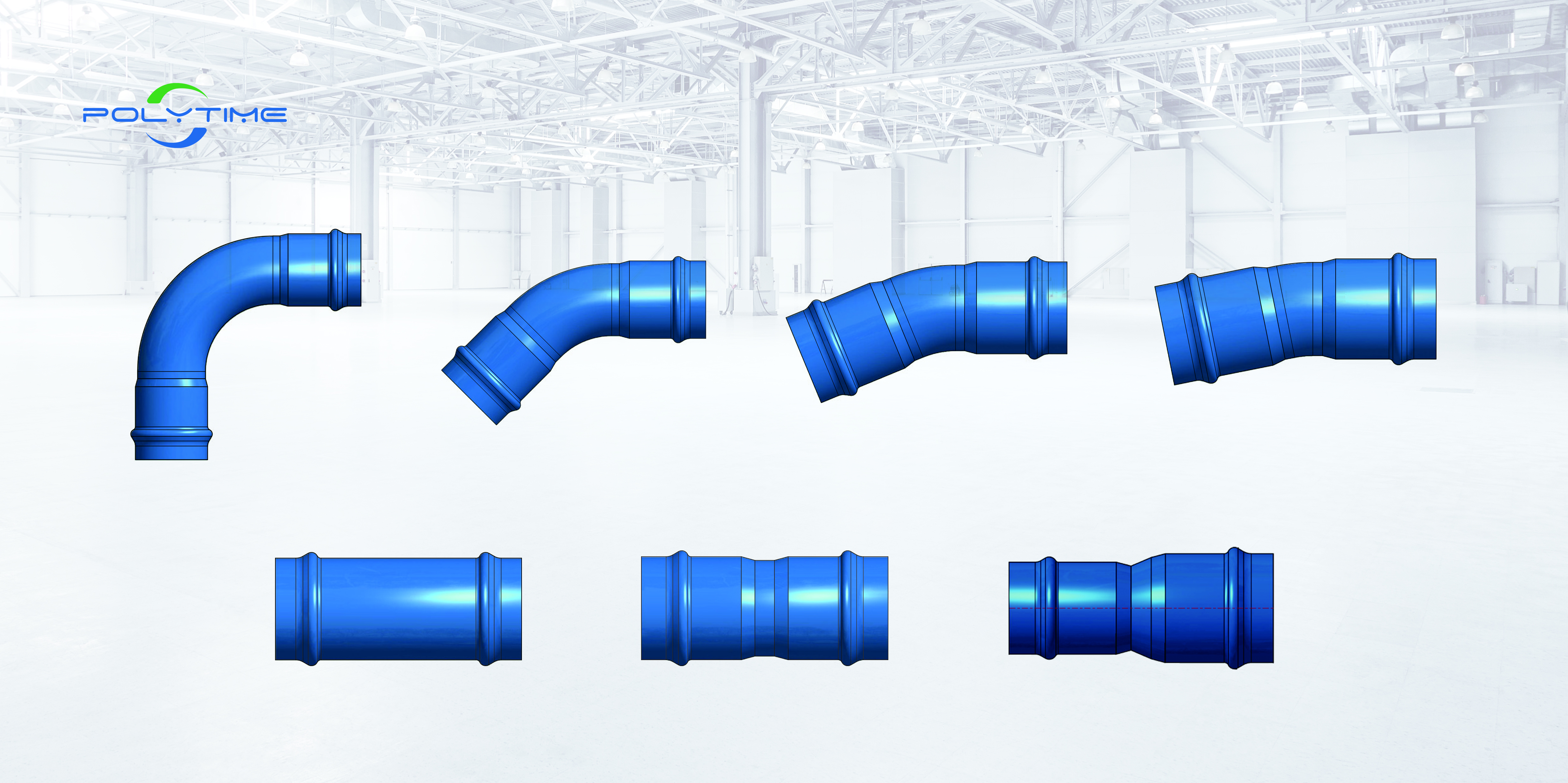

22.5° Socketed Bend

InquireCustomized Fittings for OPVC Pipes

PVC-O fittings significantly enhance the mechanical properties of conventional PVC, resulting in superior performance across multiple aspects. These improvements enable a reduction in both raw material usage and energy consumption, while delivering higher hydrostatic pressure resistance and greater impact strength compared to fittings made from other materials. Moreover, PVC-O fittings exhibit excellent behaviour against water hammer, ensure complete watertight integrity, and offer outstanding chemical resistance and ductility.

22.5° Socketed Bend

OPVC fitting diameter: DN110 mm to DN400 mm

OPVC fitting pressure:PN 16 bar

Advantages of OPVC Fitting

● High Impact and Crack Resistance

The molecularly oriented structure provides exceptional toughness, making the fittings highly resistant to impact, pressure surges, and water hammer, even in cold conditions.

● High Pressure Resistance

They can withstand very high internal pressures, allowing for the use of pipes with thinner walls (compared to PVC-U) while maintaining strength. This leads to a higher pressure rating for the same outer diameter.

● Lightweight

Despite their high strength, PVC-O fittings are remarkably lightweight. This simplifies handling, transportation, and installation, reducing labor time and costs.

● Long Service Life

They are highly resistant to corrosion, chemical attack (from aggressive soils and most fluids), and abrasion, ensuring a long and reliable service life of 50+ years.

● Excellent Hydraulic Characteristics

The smooth internal surface minimizes friction loss, allowing for greater flow capacity and reduced pumping costs compared to traditional materials.

● Environmental Sustainability

They have a low carbon footprint due to energy-efficient manufacturing. Their smooth bore reduces energy needed for pumping. Additionally, they are 100% recyclable.

● Leak-Free Joints

When used with compatible, purpose-designed jointing systems (like elastomeric seals), they create reliable, leak-free connections, enhancing the efficiency of the entire pipeline system.

● Cost-Effectiveness

The combination of long life, low maintenance, easy installation, and superior hydraulic performance makes PVC-O a highly cost-effective solution over the total lifecycle of the system.